marcochezzi

Active member

So for what seems like a lifetime, I have been watching my health, patience and humour decline thanks to a key client's inability to make +150 days payments, this despite their MD enjoying +R130 bar annual income, before benefits..

I am frustrated beyond words, not only in the seemingly nauseating capitalistic economies of scale, but in the absolute lack of common sense and general business ethicality that seems to prevail when large 'monopolies' take on the services of smaller vendors to further their ways..

So, when the chips are down, go into the garage, turn on the old lathe and mill and make more chips.. While it does not improve the financial situation, it sure as hell beats yelling at those that cannot or care not to hear, all day long..

I think its pretty well understood that I like to play on these old dinosaurs, I still have one Revox B77 which is fairly standard albeit with a lick of paint, and since I had purchased some of the key ingredients for a change some months back, the opportunity presented itself once more to finish the last of my stock, to the level which I want her to be..

Some history - The machine came partnered with a C270 that I had bought off a forum member what must be 2 years back, maybe less, come to think of it she might even have been on of the two I had acquired from FDLSYS a very long time ago, not sure, cannot really tell, but somewhere in her first landing on my shores in fairly sorry state to now, she was made over and actually worked really well, so why the hell leave her alone then..??

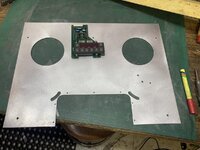

A while ago I decided to take an old B77, convert it to high speed 2 track, convert it to flat face, and then convert it to real time count, cause why, cause that's how I like it.. And so it was..

Then another while passed and I decided to try my luck at incorporating the PR-99 MK2 digital count and locator functionality into another flat faced B77 as an opportunity presented itself on facebook when the locator board and respective display and control card became available, followed by the headblock assembly which housed the original Revox count encoder wheel pulley thing.. And so it was..

And since there were two, why not go for three right, I mean, if not why not.. Cannot even remember if I had gotten in touch with the original locator board vendor and asked if he might just maybe have one more set in stock.. "yep", he said..

What about the headblock assembly?? "yep" he said..

So I got them, stored them in a drawer where they lay dormant for a long long long time..

Then by virtue of the powers of the audio Gods, and nature, I got to meet Charles, telephonically, because there were odds and ends that I needed, predominantly a complete set of brake bands for the B77 and I had stupidly trashed mine by dropping a 3 jaw lathe chuck on the assembly, by mistake of course, sending the lot to RTR heaven, and he happened to get in touch....

So after some mutual to and fro comms I made a much needed turn past Charles's place, where I was met by his lovely wife, a few nutty dogs and a plethora of beautiful valve jobbies that I would like to add to my collection too one day, not necessarily his, but if they go on the market and the green stuff is flowing a little better than today then who knows, just maybe..

Landed up driving away that afternoon with a set of perfectly functional undamaged brake bands, with the rest of a somewhat 'abused' mono PR-99 MK1 with destroyed audio electronics attached to the much needed braking mechanism..

This lent itself to some use, to which the third bastard musketeer was born..

I am frustrated beyond words, not only in the seemingly nauseating capitalistic economies of scale, but in the absolute lack of common sense and general business ethicality that seems to prevail when large 'monopolies' take on the services of smaller vendors to further their ways..

So, when the chips are down, go into the garage, turn on the old lathe and mill and make more chips.. While it does not improve the financial situation, it sure as hell beats yelling at those that cannot or care not to hear, all day long..

I think its pretty well understood that I like to play on these old dinosaurs, I still have one Revox B77 which is fairly standard albeit with a lick of paint, and since I had purchased some of the key ingredients for a change some months back, the opportunity presented itself once more to finish the last of my stock, to the level which I want her to be..

Some history - The machine came partnered with a C270 that I had bought off a forum member what must be 2 years back, maybe less, come to think of it she might even have been on of the two I had acquired from FDLSYS a very long time ago, not sure, cannot really tell, but somewhere in her first landing on my shores in fairly sorry state to now, she was made over and actually worked really well, so why the hell leave her alone then..??

A while ago I decided to take an old B77, convert it to high speed 2 track, convert it to flat face, and then convert it to real time count, cause why, cause that's how I like it.. And so it was..

Then another while passed and I decided to try my luck at incorporating the PR-99 MK2 digital count and locator functionality into another flat faced B77 as an opportunity presented itself on facebook when the locator board and respective display and control card became available, followed by the headblock assembly which housed the original Revox count encoder wheel pulley thing.. And so it was..

And since there were two, why not go for three right, I mean, if not why not.. Cannot even remember if I had gotten in touch with the original locator board vendor and asked if he might just maybe have one more set in stock.. "yep", he said..

What about the headblock assembly?? "yep" he said..

So I got them, stored them in a drawer where they lay dormant for a long long long time..

Then by virtue of the powers of the audio Gods, and nature, I got to meet Charles, telephonically, because there were odds and ends that I needed, predominantly a complete set of brake bands for the B77 and I had stupidly trashed mine by dropping a 3 jaw lathe chuck on the assembly, by mistake of course, sending the lot to RTR heaven, and he happened to get in touch....

So after some mutual to and fro comms I made a much needed turn past Charles's place, where I was met by his lovely wife, a few nutty dogs and a plethora of beautiful valve jobbies that I would like to add to my collection too one day, not necessarily his, but if they go on the market and the green stuff is flowing a little better than today then who knows, just maybe..

Landed up driving away that afternoon with a set of perfectly functional undamaged brake bands, with the rest of a somewhat 'abused' mono PR-99 MK1 with destroyed audio electronics attached to the much needed braking mechanism..

This lent itself to some use, to which the third bastard musketeer was born..

Last edited: